Our Power Distribution Panels are using in application like power distribution, ground-fault protection and monitoring, apart from this Distribution Panel also serves as alarm panel for freeze protection, board

temperature-maintenance and heat-tracing applications. These Power Distribution Panels are intergrated with ground-fault circuit breakers in an enclosure having assembled circuit-breaker panel board with or without ala rms contacts.

PRODUCTS

Power Distribution Board(PCB)

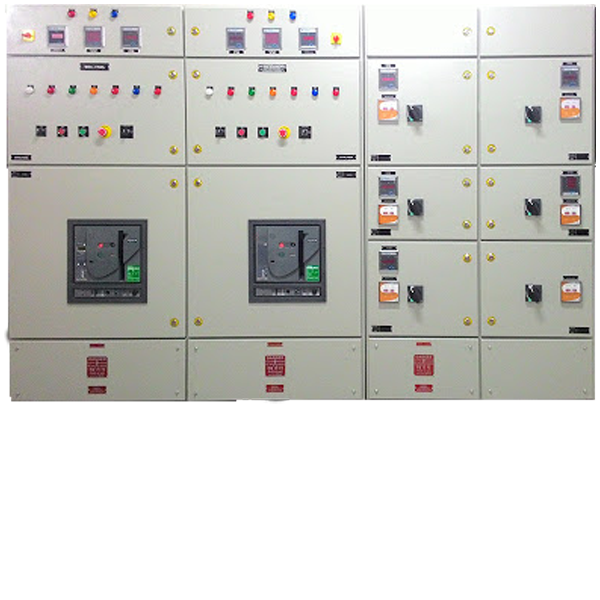

Power Control Centre

Power Control Centre is used for distribution and control of various source used in industry. Normally Power Control Centres is installed near power source hence fault level is high, Bushbar system in Power Control Centers are designed to suit the fault level as well as temperature rise to 40°C above ambient. Ample space is provided for cable termination.

Various protections viz short circuit, overload, earth fault under voltage etc. are provided to protect source and equipment.

Power Control Centre

Power Control Centre is used for distribution and control of various source used in industry. Normally Power Control Centres is installed near power source hence fault level is high, Bushbar system in Power Control Centers are designed to suit the fault level as well as temperature rise to 40°C above ambient. Ample space is provided for cable termination.

Various protections viz short circuit, overload, earth fault under voltage etc. are provided to protect source and equipment.

Motor Control Center(mcc) Panel

An Automatic Power Factor Correction (Controller) panel know as APFC Panel is used to save energy by consistently maintaining higher power factor. Low Power Factor leads to poor power efficiency, thereby increasing the apparent power drawn from the distribution network. This result is overloading panels are a modern powerful system constituting a technology breakthrough in the field of Power Factor Control. Our Automatic Power Factor Correction Panel is ready to connect, for the central compensation of reactive power in three-phase supply systems for steel Rolling Plants, Engg. Industries and Commercial Building etc.

Automatic Power Factor(APF)

An Automatic Power Factor Correction (Controller) panel know as APFC Panel is used to save energy by consistently maintaining higher power factor. Low Power Factor leads to poor power efficiency, thereby increasing the apparent power drawn from the distribution network. This result is overloading panels are a modern powerful system constituting a technology breakthrough in the field of Power Factor Control. Our Automatic Power Factor Correction Panel is ready to connect, for the central compensation of reactive power in three-phase supply systems for steel Rolling Plants, Engg. Industries and Commercial Building etc.

Automatic Power Factor(APF)

An Automatic Power Factor Correction (Controller) panel know as APFC Panel is used to save energy by consistently maintaining higher power factor. Low Power Factor leads to poor power efficiency, thereby increasing the apparent power drawn from the distribution network. This result is overloading panels are a modern powerful system constituting a technology breakthrough in the field of Power Factor Control. Our Automatic Power Factor Correction Panel is ready to connect, for the central compensation of reactive power in three-phase supply systems for steel Rolling Plants, Engg. Industries and Commercial Building etc.

Programmable Logic Controller (PLC)

Programmable Logic Controller (PLC) control panels or also known as PLC Automation are one of the most important and efficient kinds of control panels. Which are generally used in variety of electronic and electrical circuit fittings. PLC Control Panels we manufacture are highly capable of giving higher output at less power consumption, integrated with solid PLC

Logic and flawless PLC hardware programming. We are engaged in designing and manufacturing of PLC & Automation Panels that is widely appreciated for longer service life and high efficiency. All these panels are hard wired. PLC based and electrically controlled and is used for various machines.

Sub Distribution Panel or Board

The Sub Distribution Panel or Board consists of a basic frame with all the necessary electrical components such as main isolating switches, emergency shut-down mechanism. RCD’s, line circuit breakers, controls and contractors for individual workgroups. The distributor can supply multiple workgroups with electrical power independently. We design and manufacture the Sub Distribution Panel according to the Customer’s need through reliability. Selectivity, durability and time of taking action to Product Quality which comply with cost effective, long life and application-wise.

Sub Distribution Panel or Board

The Sub Distribution Panel or Board consists of a basic frame with all the necessary electrical components such as main isolating switches, emergency shut-down mechanism. RCD’s, line circuit breakers, controls and contractors for individual workgroups. The distributor can supply multiple workgroups with electrical power independently. We design and manufacture the Sub Distribution Panel according to the Customer’s need through reliability. Selectivity, durability and time of taking action to Product Quality which comply with cost effective, long life and application-wise.

High Tension Panel (HT Panel)

HT Panel is a high tension panel through which all machines get supply all the way through UG cables. It is highly preferred by our valuable clients of all across the globe due to its long lasting life, easy operation and power consumption features.

Low Tension Panel (LT Panel)

Our vast range comprises LT Panels that are manufacturing with using high quality electrical components like ACB, MCCB, SFU, Protection Relay with Aluminum and Copper Busbar as per requirement of Clients, Consultants Specification. That will be huge application in industries, Big Commercial Complex, these LT Panel are designed in such a manner that installed in substation to enable to for proper Power Distribution selective fault protection & contact isolation capabilities.

LT Panel are designed with such a manner that single/Multiple incomer, Bus coupler with proper interlocking to enable for power distribution selective fault protection & selective. Fault level will be maintained with Transformer specifications.

Low Tension Panel (LT Panel)

Our vast range comprises LT Panels that are manufacturing with using high quality electrical components like ACB, MCCB, SFU, Protection Relay with Aluminum and Copper Busbar as per requirement of Clients, Consultants Specification. That will be huge application in industries, Big Commercial Complex, these LT Panel are designed in such a manner that installed in substation to enable to for proper Power Distribution selective fault protection & contact isolation capabilities.

LT Panel are designed with such a manner that single/Multiple incomer, Bus coupler with proper interlocking to enable for power distribution selective fault protection & selective. Fault level will be maintained with Transformer specifications.

Compact Substation

It comprises of factory built sheet metal enclosure housing MV Switchgear, Transformer, LT Switchgear, Power Factor Correction System, and other site specific requirement.

Distribution Transformer

Capacity:

25 KVA to 5000KVA

Distribution Transformer

Capacity:

25 KVA to 5000KVA

Automatic Servo Voltage Stabilizer

Capacity:

30 KVA to 4000KVA

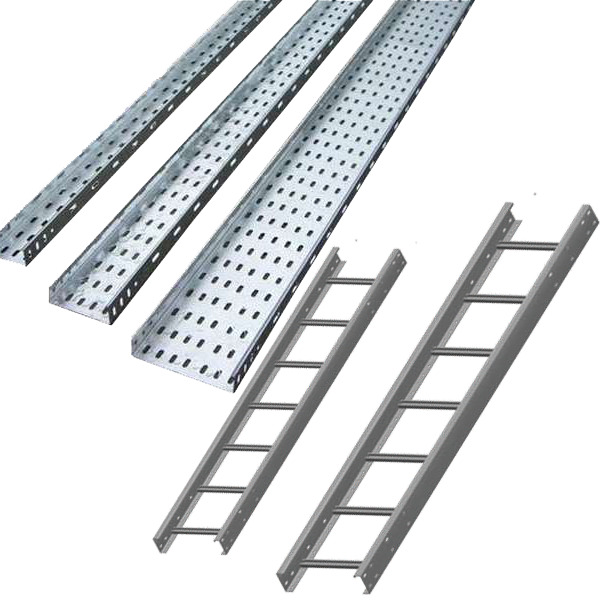

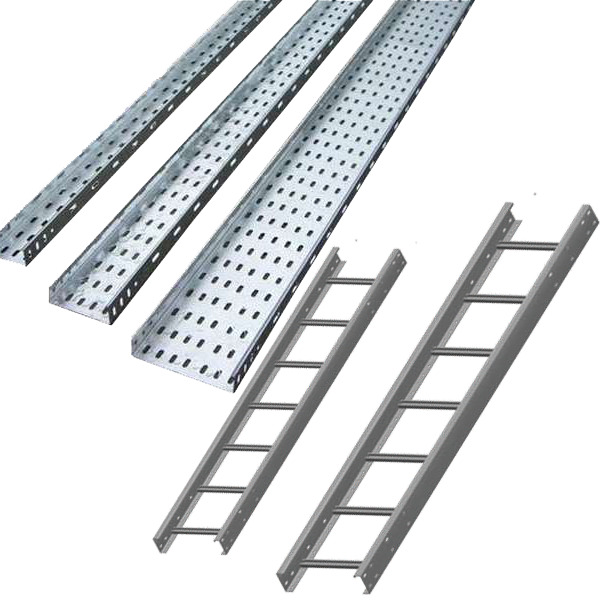

Cable Tray & Ladder Tray

cable tray system is used to support insulated electrical cables used for power distribution, control, and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe.

Cable Tray & Ladder Tray

cable tray system is used to support insulated electrical cables used for power distribution, control, and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe.